DURAPAK

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to DURAPAK

Mobile Shrinking For Heavier Objects

Durapak introduces an unique way to handle heavier objects especially the one they look to shrink wrap our mobile shrink stations with heat shrink tools and heat production device helps our customers to get an easy solution to shrink wrap heavier products or even with the products with indefinite shape and size.

L Sealer And Tunnel

We offer semi-automatic shrink wrapping machines and tunnels. This is apply to all companies where packing flexibility, product quality and limited investment are fundamental parameters. Technically and aesthetically updated in recent times, the modular series can offer excellent performances with any kind of packing material (polythene too) thanks to the self-regulating electronically controlled temperature sealing system and the most advanced safety systems. The possibility of an automatic or semiautomatic operation in combination with the possibility of customizing the 6 programs make modular a user-friendly and high-output machine, also thanks to the built-in (standard) film rewinder and the possibility of perfectly interfacing with the new tunnel 50 and tunnel 70.

Auto Shrink Wrapping Machine

Modularity and excellent price/quality ratios are the main features characterizing the fully automatic sealers of the FP series. All the models of this range can indeed be supplied with or without shrink tunnel.

Compared to the traditional L-sealing hood packers, the FP series provides higher outputs as well as the possibility of using Polyethylene film, besides the traditional shrink films.

The FP series of modular sealers with shrink tunnel includes different models, for outputs ranging up to 6.000 packs/hour.

Side Seal Shrink Wrapping Machine

Poor shrink package quality is often the result of non-intuitive mechanical adjustments, dependence on precise time, speed and temperature control and changes in seal quality due to dirt and/or film build-up. Durapak shrink wrappers are designed to address all of these issues and more. durapak revolutionary high speed shrink wrappers eliminate many of the common shrink wrapping problems that result in poor package quality.

Durapak FP series high speed shrink wrappers will significantly improve productivity levels by reducing rework as a result of poor package quality and reduce downtime due to time consuming change-overs.

Auto Sleeve Wrapping Machine

Automatic sleeve sealing machine with shrink tunnel is designed for packing single product or combined products without tray. the equipment can be connected with the production line to complete feeding, film wrapping, sealing & cutting, shrinking and cooling automatically. There are various packing modes available. For combined object, the bottle quantity can be 6, 9, 12, 15, 18, 20 or 24 etc.

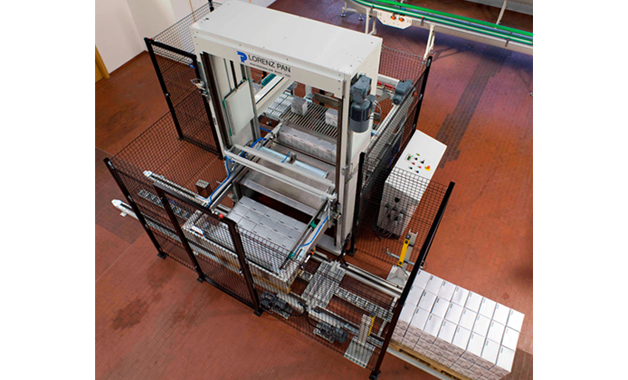

Palletiser

Features:

Robust-and material efficient design

Low energy and maintenance cost

High quality components

Simple and fast installation and start-up

System options are easy to add – if required at a later stage (pallet dispenser, pallet roller conveyor and layer sheet application)

Left or right infeed, easy to change.

Semi Automatic Taping Machine

Durapak is known as one of the most leading suppliers of high quality Semi-Automatic Semi Automatic Taping Machine. Different types of our technically advanced carton sealing and taping machines are available at market leading prices if you are searching high performance carton sealing machine for your specific requirements.

Features:

- New taping head incorporating a v shaped plate (patented) designed to keep the tape straight and in position for consistent sealing of every carton. This design is superior to previous blower devices.

- Flexible cushion prevents box been jammed under the top tapping head.

- Tape overlap length can be adjusted from 55~65 mm, tape overlap of 70+-5 or 90+-5mm can be provided on request.

- Wider belt-75mm firmly seize the carton, new "linking buckle" design allowing the belt to be changed easily.

- Over sized drive rollers guide belt design stops slipping and prolongs belt life.

- Aluminum guide mechanism allow tape head bracket to move very stable and smooth.

- Both side guide rails can be adjusted separately to meet the carton width.

- Driven by two side drive belts or top & bottom drive belts, each belt has a separate drive mechanism using a special bearing bracket. This provides higher precision, lower noise and lengthens belt life.

Case Errectors

Features:

Carton erector automatically form and bottom seal different styles and size of cartons. After that is perfectly-form empty carton that are ready to be filled and can integrate any carton sealers to seal top flops. So form, pack and seal carton is all in one operation.

With no tape detector, erecting failure detector, bottom sealing failure detector, no cartons at the magazine detector. All ensure to solve the problems at the short time.

Human machine interface Mechanism (Touch control panel)

New taping head incorporating a V shaped plate (patented) designed to keep the tape straight and in position for consistent sealing of every carton. This design is superior to previous blower devices.

Driven by power side belts, main drive mechanism adopt self-aligning ball bearing bracket providing exact and precise sealing, lower noise and lengthening belt life.

Equipped with double type vacuum sucking arm to erect cartons more film.

Professional safety fence with aluminum frame provide more safety working environment.

Easy change & simple adjustment to increase production efficiency.

Minimum maintenance, durability and run good performance.

Carton Stretch Wrapping Machines

Durapak Carton Stretch Wrapping Machines are a simple and convenient device to wrap carton boxes and objects of similar geometry using stretch film delivered from Powered Pre-Stretch Unit.

Stretch Wrapped Protection can be given to small medium sized objects packed in carton boxes, cans, tins, drums, etc.

This is highly suitable for goods with light weight that can be manually loaded, turned over, wrapped and unloaded from the machine.

This machine can be easily integrated into conveyor lines.

Horizontal Orbital Automatic Wrapping Machine

COMPACTA S 4 – Horizontal Orbital Automatic Wrapping Machine

The Compacta series machines are built following high quality criteria and construction specifications that have been improved and refined through time. The high degree of satisfaction generated worldwide by the Compacta Automatic series makes these machines the top preference of final users, which entrust their products to horizontal wrapping technology using stretch film.

Thanks to a wide range of ring diameters this line of machines manufactured by Robopac covers completely a broad range of wrapping needs. Compacta S is a machine that combines construction sturdiness with top-level automatic wrapping operations.

The versatility of use and the user friendliness of Compacta S, combines with high quality level that distinguishes them and places also these Robopac products at the top of their categories.

Robot Pallet Stretch Wrapping Machine

Self-Propelled Robot for Packaging with stretch film

The new ROBOT S6, wrapping machines, positions Robopac as the best partner for all manufacturers who require maximum warehouse logistics and management. Robot S6 demonstrates its leadership due to the new technical innovation for simplifying its use.

ROBOT S6 is designed and produced according to the policies that distinguish Robopac in terms of reliability and durability. Every single detail was designed selecting the best materials on the market. No detail was left behind and the hi-tech solutions and craftsmanship can be seen in each inch of the machine.

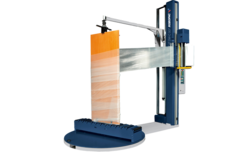

Turntable Stretch Wrapping Machines

New generation Robopac series 8 Turntable Stretch Wrapping Machines are our most popular general purpose stretch wrappers which are designed to wrap the majority of all pallet loads.

It's a perfect fit for the semi-automatic environment as it can be loaded with a pallet jack or fork truck.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.